Quality Control

We have a well-designed and strict inspection process, with state-of-the-art measuring equipment to ensure high quality products. Our mechanics will pay great attention to monitor the production flow and inspect every part as they are run. New parts and articles will be specially examined. In addition, all parts will go through a final inspection on our advanced inspection facilities.

Quality inspecting equipment:

INSPECTOR S bridge type CMM (Coordinate Measuring Machine)

5-dimensional measuring instrument

Service

We have a professional engineer team to design custom parts for your remand, we also have a lot of ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production design and mould design base on your requirement . We will provide qualified sample and confirm all the details with clients, to ensure continuous and stable delivery of mass production.

According to our work record, the defective rate has been maintained within 1%.Secondly, for defective batch products, we will conduct an internal review and communicate with the customer in advance, and resend them to you. Alternatively, we can discuss solutions based on the actual situation, including recalling.

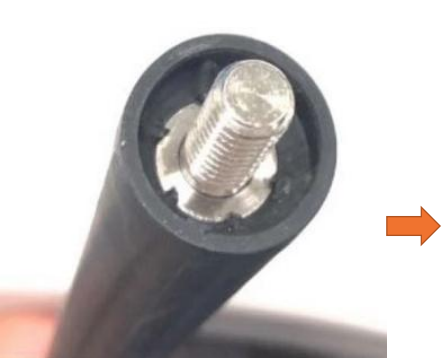

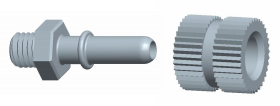

Following are some of our OEM works we have done for our clients.

OEM Sampls-CNC Turing parts

OEM Samples Non-Standard Metal

OEM Samples-Auto Parts